Research Article

Evaluation of the Dimensional Stability of an Irreversible Hydrocolloid Modified by the Addition of Condensation Silicone

- Antônia Edivanda Aguiar Parente 1

- Isabella Fechine de Oliveira 1

- Jozely Francisca Mello Lima 2

- Daniel Sartorelli Marques de Castro 3

- Jaqueline Alves do Nascimento 4*

1 Dental Surgeon, Christus University Center, Fortaleza-Ceará/Brazil.

2 Doctorate in Oral Rehabilitation Bauru Dentistry School/ University of São Paulo, Adjunct Professor Prosthodontics and Occlusion Federal University of Ceará-Sobral, Brazil.

3 Doctorate in Oral Rehabilitation Bauru Dentistry School/ University of São Paulo, Professor Christus University - Unichristus / Brazil.

4 Department of Dental Implant, Prosthodontics and Periodontics at Ceará Institute of Dental Specialties, Valdevino, Fortaleza-CE, Brazil.

*Corresponding Author: Jaqueline Alves do Nascimento, Department of Dental Implant, Prosthodontics and Periodontics at Ceará Institute of Dental Specialties, Valdevino, Fortaleza-CE, Brazil.

Citation: AEA Parente, Isabella F Oliveira, JFM Lima, DSM Castro, Jaqueline A Nascimento. (2023). Evaluation of the Dimensional Stability of an Irreversible Hydrocolloid Modified by the Addition of Condensation Silicone. Clinical Case Reports and Studies, BRS Publishers. 2(1); DOI: 10.59657/2837-2565.brs.23.004

Copyright: © 2023 Jaqueline Alves do Nascimento, this is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Received: October 28, 2022 | Accepted: December 22, 2022 | Published: January 02, 2023

Abstract

Knowing the properties and clinical indications of each material ensures that the dental surgeon can use techniques that guarantee better results for dental prostheses. This study aims to evaluate the dimensional stability of an irreversible hydrocolloid modified by the addition of silicone by condensation.

During this evaluated the dimensional distortion of irreversible hydrocolloids according to conditioning time, for four commercial brands, being: Avagel (Dentsply), Hydrogum 5 (Zhermack Spa) and Jeltrate Plus (Dentsply) and Avagel plus Condensation Silicone (Zetaplus [Zhermach]). They were placed in a container with 100% humidity, and the following requirements were evaluated: weight, height, and length of the three groups during the following times: immediately, 24 hours, 48 hours, 72 hours, and 120 hours.

All materials evaluated showed adequate dimensional stability within the initial 72 hours. The addition of condensation silicone to the irreversible hydrocolloid mixture did not improve the dimensional stability of the material.

Keywords: dental molding technique; molding; dental prosthesis

Introduction

Modern restorative dentistry has a wide variety of impression materials with different clinical applications [1]. The first impression materials to show clinically adequate results were elastomers, with the first reports of the use of polysulfides presented in the 1950s. Still at that time, silicones appeared, and only 10 years later, polyether-based materials appeared. The emergence of these new impression materials enabled a reduction in working time and greater fidelity in the reproduction of details [2].

Since World War II, irreversible hydrocolloids, also called alginate, have been considered the most widely used impression materials in dentistry today, the material of choice for obtaining both study models, in common plaster, type III or stone, and working models, in stone and/or special plaster, total or partial dentate [3].

The main limitation of irreversible hydrocolloids is the volumetric change that the mold presents after being removed from the mouth. Because it is a dimensionally unstable material, when the mold is exposed to air and room temperature, some contraction associated with syneresis and evaporation tends to occur, and when immersed in liquid, it tends to expand due to the soaking property [4].

Elastomers are polymers in which the setting (polymerization) occurs through chain lengthening and crosslinking (i.e., between chains). Polymerization can be either condensation (with by-products) or addition (without by-products) and occurs at room temperature. When polymerized, elastomers are solid, visco-elastic. Thus, they can reproduce the oral structures with high precision and level of detail, and are recommended for clinical cases that require high precision and have different characteristics regarding dimensional stability; however, this limitation can be compensated provided that the casting time recommended by the manufacturer is respected [5].

This study aims to evaluate the dimensional stability of an irreversible hydrocolloid modified by the addition of silicone by condensation.

Materials and Methods

Division of the Groups

To perform the evaluation of the dimensional stability of the materials, three experimental groups were created, distributed as follows:

Table 1: Composition of the experimental groups.

| Group I Positive Control | N=15 | Avagel |

| Group II Negative Control | N=15 | Hidrogum 5 |

| Group III Experimental | N=15 | Ava Gel + Silicone Condensation |

Composition of the Experimental Groups

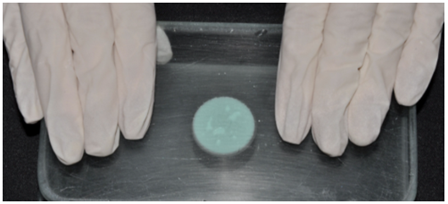

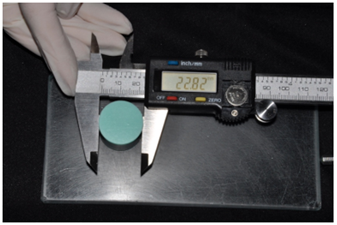

Five circular plastic matrices were selected, with the following characteristics: 23.50 mm in height and 17.9 mm in circumference [Figure1]. Using the matrices, 15 samples were made for each experimental group [Figure 2], each sample measuring 22.82mm in circumference and 17.79mm in height (Figure 4 and 5). The materials [Table 2] were proportioned (powder + liquid), following the manufacturers' instructions. After manipulating each material, they were placed in the plastic matrices and then positioned between two glass plates [Figure 3], whose objective was to leave the material without bubbles and within the limits of the matrices. After the samples had gelled, they were removed and placed in a humidifier, in order to preserve their integrity.

Figure 1: Plastic Matrices.

Figure 2: Plastic Matrices and Sample.

Figure 3: Accommodation of the manipulated material inside the matrices, with the help of a glass plate at the bottom and another at the top.

Figure 4: Specimen being measured with digital caliper in circumference.

Figure 5: Specimen being measured with digital caliper in height.

Table 2: Manufacturers' instructions for proportioning, handling and storage of samples, according to manufacturers' information.

| Materials | Avagel * | Hidrogum 5* | Precise SX Fluido |

| Proportioning | 8,5gr Powder / 18ml Liquid | 7gr Powder / 15ml Liquid | 1:1 Base / Catalisador |

| Mixing Time | 30" | 30" | 30" |

| Working Time | 1’ | 1’05” | 2’ |

| Hardness Time | Indicated by the color change | 1'50" | 3’30” |

| Storage | Hermetically sealed package at 23C. | Hermetically sealed package at 23C. | Ambient at 23C. |

Dimensional Stability Assessment

Each sample belonging to the experimental groups was evaluated at the following times in Table 3.

Table 3: Evaluation times for each sample of the groups.

| T1 | T2 | T3 | T4 | T5 |

| Immediately | 24h | 48h | 72h | 120h |

The evaluation of the dimensional stability of the samples was performed using a digital pachymeter and a digital scale, where the data referring to the size of the samples and their weight will be tabulated and statistically evaluated.

Statistical Analysis

For statistical evaluation, ANOVA tests were used, for independent or repeated measures, followed by Bonferroni post-test (parametric data) (SPSS 20.0 for Windows, p<0>

Results

Based on the results regarding time, we obtained the following data, as shown in tables 4, 5 and 6.

Table 4: Time and Weight of Samples - Different lowercase letters = significant difference between times; different uppercase letters = significant difference between groups; *ANOVA test for repeated measures/Bonferroni; †ANOVA/Bonferroni test (Media ± SD).

| Moment of Evaluation | ||||||

| Day 1 | Day 2 | Day 3 | Day 4 | Day 5 | p-Value* | |

| Weight | ||||||

| Group I | 9,00±0,00Aa | 9,00±0,00Aa | 9,00±0,00Aa | 9,00±0,00Aa | 9,00±0,00Aa | 1,000 |

| Group II | 9,00±0,00Aa | 9,00±0,00Aa | 9,00±0,00Aa | 9,00±0,00Aa | 9,00±0,00Aa | 1,000 |

| Group III | 9,00±0,00Aa | 9,00±0,00Aa | 9,00±0,00Aa | 8,33±0,49Bb | 8,27±0,46Bb | <0> |

| p-Value† | 1,000 | 1,000 | 1,000 | <0> | <0> | |

Table 5: Time and Height of Samples - Different lowercase letters = significant difference between times; different uppercase letters = significant difference between groups; *ANOVA test for repeated measures/Bonferroni; †ANOVA/Bonferroni test (Media ± SD).

| Moment of Evaluation | ||||||

| Day 1 | Day 2 | Day 3 | Day 4 | Day 5 | p-Value* | |

| Height | ||||||

| Group I | 17,68±0,36Aa | 17,65±0,20Aa | 17,69±0,16Aa | 17,78±0,14Aa | 17,75±0,16Aa | 0,384 |

| Group II | 17,52±0,19Aa | 17,53±0,23Aa | 17,47±0,16Ba | 17,58±0,20Ba | 17,63±0,08Ab | 0,049 |

| Group III | 17,66±0,21Aa | 17,54±0,21Aa | 17,49±0,19Ba | 17,62±0,18Aa | 17,60±0,12Bb | 0,031 |

Table 6: Time and Width of Samples - Different lower-case letters = significant difference between times; different upper-case letters = significant difference between groups; *ANOVA test for repeated measures/Bonferroni; †ANOVA/Bonferroni test (Media ± SD).

| Moment of Evaluation | ||||||

| Day 1 | Day 2 | Day 3 | Day 4 | Day 5 | p-Value* | |

| Width | ||||||

| Group I | 22,34±0,35Aa | 22,52±0,19Aa | 22,48±0,21Aa | 22,59±0,22Aa | 22,68±0,24Ab | 0,046 |

| Group II | 22,28±0,20Aa | 22,44±0,22Aa | 22,43±0,09Aa | 22,56±0,18Ab | 22,57±0,16Ab | 0,022 |

| Group III | 22,31±0,23Aa | 22,36±0,20Aa | 22,33±0,18Aa | 22,43±0,11Ba | 22,54±0,14Ab | 0,014 |

| p-Value† | 0,841 | 0,097 | 0,057 | 0,041 | 0,095 | |

Discussion

In this work, three different irreversible hydrocolloids were evaluated, divided into three groups; weight, height and width evaluations of each of the samples were performed.

Regarding weight, the samples belonging to groups 1 and 2 remained stable, with no alteration in the weight of the samples on the five days of evaluation. In group 3, the samples suffered weight alterations after the 4th day of evaluation, presenting values of 8,330.49 (day 4) and 8,270.46 (day 5), below the values found in the first three days of evaluation. This behavior can be explained by the change in the physical properties of the material, due to the addition of condensation silicone in the mixture, which generated a greater loss of water or a high shrinkage of the samples.

When the height of the samples was evaluated, it was possible to observe that those from group 1 did not present statistically significant differences on the five days of evaluation, although the values indicated a small increase as of day 4. In group 2, there was a change in the height of the samples on the 3rd day of evaluation. It is possible to notice a decrease and, after this, an increase in the volume of the samples. Finally, in group 3, the samples followed the same behavior as those evaluated in group 2. It was possible to observe a decrease in the height of the samples on the 3rd day, and after this, there was an increase, and then a new decrease in height. Therefore, the samples in group 2 and 3 presented statistically significant differences when compared to those in group 1.

In the evaluation of the width, it was possible to observe that, in group 1, the samples presented an alteration on the 4th day of evaluation, with an increase from 22.48 to 22.680.24. In group 2, the samples had the same behavior, with a change from 17,470.16 to 17,630.08. In group 3, the samples also showed an increase from 22.33±0.11 to 22.54±0.14.

One of the causes of this change in sample size observed in the evaluations of height and width may have been caused by the absorption of water from the medium, causing an expansion of the samples. All samples were placed in a humidifier during the entire time of the study, remaining out of direct contact with the water present in the device. Furthermore, it can be inferred that the little change that occurred in group 1, composed of a material considered to be less precise among the various types of hydrocolloids, may have been due to the fact that the samples are circumferential, unlike a dental arch molding in which there are details to be reproduced. Another aspect is the fact that the other materials have modifications in their composition, which may bring a higher immediate accuracy, but without long-term dimensional stability.

Conclusion

We conclude that all materials evaluated presented adequate dimensional stability in the initial 72 hours, and that the addition of condensation silicone in the irreversible hydrocolloid mixture did not bring an improvement in the dimensional stability of the material.

Thus, further research is needed to demonstrate that the addition of this material (elastomer) to alginate can improve the ability to reproduce details.

References

- Donovan TE, Chee WWL. (2004). A review of contemporary impression materials and techniques. Dental Clin N Am. 48:445-470.

Publisher | Google Scholor - Shillingburg JR, H.T. et al. (1986). Fundamentos da Prótese Fixa. Quintessence Editora, Rio de Janeiro.

Publisher | Google Scholor - Naylor WP, Evans DB. (1989). An overview of impression materials and techniques for fixed prosthodontics. In: Land MF, ed. Clark's clinical dentistry. Revista: St. Louis: Mosby.

Publisher | Google Scholor - Amorim et al. (2015). Análise da Estabilidade Dimensional do Hidrocolóide Irreversível de duas Marcas Comerciais. Brazilian Journal of Surgery and Clinical Research–BJSCR. Res. 9(3):05-10.

Publisher | Google Scholor - Craig, Robert G, Powers, John M, Wataha, John C. (2002). Materiais dentários. São Paulo: Santos Editora.

Publisher | Google Scholor