Research Article

The Effects of Watermelon Rind Flour on The Proximate Properties of Wheat Cake

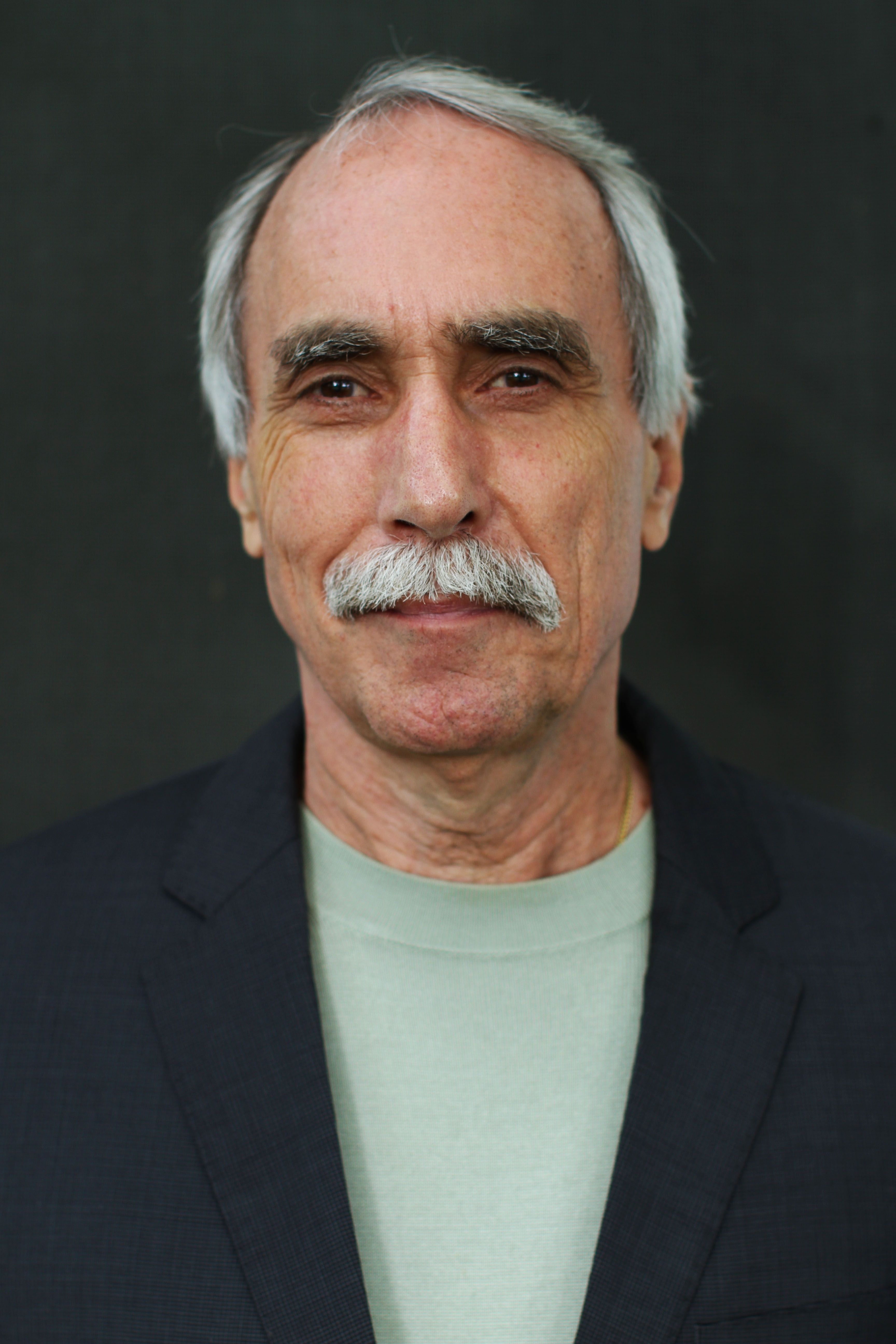

1Department of Industrial Chemistry, Mewar International University, Abuja-Keffi, Expressway, Masaka, Nasarawa State, Nigeria.

2Department of Chemistry, University of Benin, Benin City, Nigeria. P.M.B.1154, Benin City.

*Corresponding Author: C. Imoisi., Department of Industrial Chemistry, Mewar International University, Abuja-Keffi, Expressway, Masaka, Nasarawa State, Nigeria.

Citation: C. Imoisi, J.U. Iyasele, D.O. Ikpahwore and A.O. Okpebho. (2023). The Effects of Watermelon Rind Flour on the Proximate Properties of Wheat Cake.”. International Journal of Nutrition Research and Health, BRS Publishers. 2(1); DOI: 10.59657/2871-6021.brs.23.004

Copyright: © 2023 C. Imoisi, this is an open-access article distributed under theterms of the Creative Commons Attribution License, which permits unrestricted use,distribution, andreproduction in any medium, provided the original author and source arecredited.

Received: February 28, 2023 | Accepted: March 14, 2023 | Published: March 21, 2023

Abstract

Background and Objective: The present study was undertaken to develop bread from composite flours, the chemical effects of citrus flour at different replacement levels (0%, 10%, 20%, 30%, 40%) on the proximate properties of composite wheat flour were evaluated. Materials and Methods: Composite flours were prepared by blending wheat flour and watermelon flour in the ratios of 100:0 (AB1), 90:10 (AB2), 80:20 (AB3), 70:30 (AB4) and 60:40 (AB5) respectively. The blends were analyzed for proximate properties using standard methods. Results: Proximate results indicated increased level of protein and decreased level of fat (2.20%-7.80%) and (18.30%-10.40%) respectively. While carbohydrate maintained almost a similar level although there was a slight increase in the 80:20 blend (63.50%-66.64%) and an increase in ash content (0.30%-1.90%) with increasing level of watermelon flour. Conclusion: Thus, the results indicate that by incorporating watermelon flour, it is possible to enhance the nutritional quality, and proximate properties of wheat flour.

Keywords: wheat flour; watermelon rind flour; proximate composition; fat; protein; carbohydrate

Introduction

Composite flours may be considered firstly as blends of wheat and other flours for the production of leavened breads, unleavened baked products, pastas, porridges, snacks foods and cakes; or secondly, wholly non-wheat blends of flours or meals, for the same purpose [1]. Sometimes, only flour is used as replacement-for example, tortillas and wheat-less bread from sorghum, pastas from sorghum or maize. It should be noted that there are two reasons for mixing the wheat with other flours i.e., economic and nutritional [1]. Using blends, now called composite flours (CF), of wheat and other flours for bread making has always occurred in times of scarcity of wheat, from whatever cause, climatic or economic. As ingredients are being blends in composite flour may be cassava, maize, rice, sorghum, the millets, potato, barley, sweet potato and yam. In selecting raw materials for use as alternatives one must consider factors, such as (a) Compatibility- that is to say, suitability for end use and (b) availability and cost at point of use [2].

Composite flours are quite different from the ready-mixed flours familiar to millers and bakers. Composite flours are only a mixture of different vegetables flours rich in starch or protein, with or without wheat flour, for certain groups of bakery products [3]. This gives rise to the following definition: “Composite flours are a mixture of flours from tubers rich in starch (e.g., cassava, yam, sweet potato) and/or protein rich flours (e.g., soy, peanut) and/or cereals (e.g., maize, rice, millet, buckwheat), with or without wheat flour” [1]. In another words, “A flour made by blending or mixing varying proportion of more than one non-wheat flour with or without wheat flour and used for production of leavened or unleavened baked or snack products that are traditionally made from wheat flour and increase the essential nutrients in human diet is called composite flour” [4].

Consumers are currently looking for practical foods that are easy to prepare and that provide, along with nutritional quality, welfare and benefits to the health. Thus, functional foods have been developed by incorporating proteins, fibers, minerals and/or antioxidants [5]. Globally, the functional food market has been segmented as follows: fiber-based products (40%); products rich in calcium (20%); oligosaccharide-based products (20%); products containing lactic bacteria (10%) and others (10%). The largest markets for these products are the USA, Europe and Japan [6].

Foods “in nature” contain considerable amounts of fiber (fruits, vegetables and grains), as well as fibers separated in the grain processing like bran and soy fiber which are used to enrich foods. Some alternative fiber sources are already available in the market or have already been studied, including mango (Mangifera indica L.) [7], apple (Malus domestica)8, lemon (Citrus limon) [9]. and orange (Citrus sinensis L.) [10]. The addition of fiber to extruded snacks has been limited to a few fiber sources such as wheat (Triticum ssp.) and oats (Avena sativa)[11], sugar beet (Beta vulgaris) fiber, soy (Glycine max L.) fiber [12] and cauliflower (Brassica oleracea L.) fiber.

The bread and cake available in the market are prepared from wheat flour which lacks in good quality protein because of its deficiency in lysine; and dietary fibre contents [1]. Watermelon rind flour is highly nutritious in protein, vitamin, minerals and lysine content has been found for its incorporation into preparation of bread1. The study provides the information about a commercially viable application of increasing protein and fibre content in bread and also this can solve the problem of malnutrition and other essential macro and micro nutrients deficiency among the population.

No previous studies have been carried out to investigate the effects of watermelon rind flour on the proximate properties of wheat cake. Therefore, the present study was designed to evaluate the effects of watermelon rind flour at different replacement levels (0%, 10%, 20%, 30%, 40%) on the proximate properties of composite wheat flour.

Materials and Methods

Study Area and Sites

Benin City is a city found in Edo State, Nigeria. It is located at 6.34oN latitude and 5.63oE longitude and it is situated at elevation 88 metres above sea level. The population of Benin city is 1,125,058, making it the most populous city in Edo State.

Sample Collection and Analysis

Wheat was purchased from Uselu and new Benin local market, Benin City, 7kg wheat was weighed with a weighing balance in the laboratory and washed severally before soaking with 7 litres of water overnight, thereafter, the wheat was grinded with a grinder and subsequently sieved with a soft cloth sieve. The sieved wheat was sundried for seven days thereafter it was grinded again and subsequently sieved with a smaller sieve to obtain a fine wheat flour powder.

Watermelon was purchased from new Benin local market; the pulp was removed to obtain the rind (peel). The watermelon rinds were thoroughly washed under tap water and then sliced into pieces with stainless steel knives on trays and sundried for 7days. Grinding first in an electric mill before using a grinder to obtain fine rind powder of larger surface area. The fine powder was then stored in a closed container until experiment commenced.

Preparation of Cake and Incorporation with Watermelon Rind Flour

Bread was produced using the straight dough process described by Imoisi et al. [13]. Baking was carried out under laboratory conditions to optimize baking conditions. Flour and watermelon rind fiber weighing were carried out on a laboratory scale. Dough was mixed to optimum consistency in a mixer with low speed 85rpm for 1 minute. The substitution of wheat flour by watermelon rind flour was 0%, 10%, 20%, 30% and 40% for AB1, AB2, AB3, AB4 and AB5 respectively (Table 1). Fiber, sugar, yeast and other ingredients for cake were accurately added. The mixed cream was then put into medium size round calibrated pan. The cake was oven baked for 1hour 25 minutes at 100°C.

Table 1: Incorporation of wheat flour with watermelon rind flour.

| Sample Code | Classification |

| AB1 | Control (100g wheat flour) |

| AB2 | 90% wheat flour + 10% watermelon flour |

| AB3 | 80% wheat flour + 20% watermelon flour |

| AB4 | 70% wheat flour + 30% watermelon flour |

| AB5 | 60% wheat flour + 40% watermelon flour |

Proximate Analysis of the composite Cassava Flour

The proximate composition was determined using the methods described by Imoisi et al. [14]. The functionality of flours of cassava, which depends to a great extent on the starch and protein content of the flours, contribute a lot to the formulation and properties of the final product. Therefore, flours were analyzed for their functional properties. Particularly, the functional properties are required for the formulation of value-added composite bakery products. Protein (micro-Kjeldahl, Nx6.25), fat (solvent extraction) was also determined. The carbohydrate content was calculated by subtraction method.

Determination of Moisture Content

The moisture content was determined by using oven-drying method. Clean and dry Petri-dishes were weighed by using meter balance and their respective weights were recorded (W1). About 5g of the sample was weighed into the dishes (W2) spreading as much as possible. The Petri-dishes containing the sample were transferred into the oven maintained at 105oC and dried for about three hours. After three hours they were transferred to the desiccator to cool and then weighed. This process was continued until a constant weight (W3) was obtained. The loss in weight during drying in percentage was taken to be the percentage moisture content. The percentage moisture content was calculated using the following equation as cited by Imoisi and Michael [15].

% Moisture  x 100

x 100

X 100

X 100

Where W1= initial weight of empty crucible

W2= weight of empty crucible + sample before drying

W3= final weight of empty crucible + sample after drying.

Ash Determination

About 1g of finely ground sample was weighed into clean, dried pre-weighed crucibles with lid (W1). The organic matter was burned off using flame (lid remove) until the sample became charred. The crucibles were then transferred to the muffle furnace set at 550oC (lid removed). Charring was continued until a light grey or white ash was obtained. The percentage ash content was calculated using the following equation as cited by Imoisi and Michael [15].

The crucibles were then cooled in a desiccator and weighed (W2)

% Ash =  x 100

x 100

W2= weight of crucible + ash

W1= weight of empty crucible.

Crude Fat Determination

Cleaned and dried thimble was weighed as (W1) and 5g oven dried sample was added and reweighed (W2). Round bottom flask was filled with petroleum ether (b.pt 40-60oC) up to ¾ of the flask. Soxhlet extractor was fixed with a reflux condenser and adjusted the heat source so that the solvent boils gently. The thimble plus the sample were inserted into the Soxhlet apparatus and extraction under reflux was carried out with petroleum ether (40-60oC) for over 6 hours. The thimble was then removed and taken into the oven at 100oC for one hour and later cooled in the desiccator and weighed again (W3). The percentage fat content was calculated using the following equation as cited by Imoisi and Michael [15].

Discussion

As shown in Table 2, the percentage protein content of AB1 to AB [5] was significantly different from the control sample. The percentage protein increased as the level of substitution increased. This may be due to the high-water absorption capacity of the wheat flour which enabled the incorporation of protein from the watermelon rind flour [13], of course, it was observed that the percentage crude fibre increased as the substitution level increased compared to the control sample which had no watermelon rind flour. The addition of dietary fibre to bakery products also improves their nutritional quality since it makes possible to decrease the fat content, by using dietary fibre as substitutive of fat without loss of quality [17]. As can be seen in Table 2 above, the percentage fat content decreased with increase substitution level with AB5 (40% watermelon rind flour) having the lowest values of

Conclusion

The study shows that watermelon rind flour addition into wheat flour cake formulation had considerable impact on physical and chemical composition as well as the nutritional quality of cake. It may be concluded from the present study that watermelon rinds flour can be successfully incorporated into wheat flour cake formulation up to a level of 10% to 30% to yield bread and cakes of enhanced nutritional quality instead of discarding them after eating the pulp. Hence, development and utilization of such functional foods will not only improve the nutritional status of the population but also helps those suffering from degenerative diseases. This study also opened the door to further utilizing quality wheat flour and also watermelon rind from watermelon fruits which causes environmental pollution as a result of minima utilization.

Declarations

Acknowledgements

Special thanks go to the Department of Chemistry, University of Benin, Benin City and to Prof. J.U. Iyasele of the Department of Chemistry, University of Benin, Benin City for his impactful, insightful and invaluable contributions.

Recommendation

More studies should be conducted to investigate the possibility of using citrus vesicle flour as an ingredient in other food products in order to increase applications of such value-added food ingredient.

Competing Interest: The authors have declared that no competing interest exist.

Data Availability: All relevant data are within the paper and its supporting information files.

References

- Imoisi, C., J.U. Iyasele, U.C. Michael, and E.E. Imhontu. (2020). The effects of watermelon rind flour on the functional and proximate properties of wheat bread. Journal Chemical Society of Nigeria, 45(5):978-986.

Publisher | Google Scholor - Dendy, D.A.V. (1993). Review of composite flour technology in the context of Tanzania. Present a paper at the workshop entitled “Sorghum and millets marketing and utilization”. held at Acrusha, Tanzania, 3-5

Publisher | Google Scholor - Aremu, M.O., O. Olaofe, and E.T. Akintayo, (2007). Functional properties of some Nigerian varieties of legume seed flour concentration effect on foaming and gelation properties. J. Food Technol. 5(2):109-115.

Publisher | Google Scholor - Butt, M.S. and R. Batool, (2010). Nutritional and functional properties of some promising legumes proteins isolates. Pakistan J. Nutr, 9(4):373-379.

Publisher | Google Scholor - Imoisi, C., J.U. Iyasele, E.E. Imhontu, U.R. Orji and S.A. Okhale, (2021). Phytochemical and antioxidant capability of Vitex doniana (Black Plum) fruit. Journal Chemical Society of Nigeria, 46(1): 191-196.

Publisher | Google Scholor - Menrad, K, (2003). Market and marketing of functional food in Europe. Journal of Food Engineering, 56:188-191.

Publisher | Google Scholor - Rodríguez, R.A.J. J. Fernández-Bolaños, R. Guillén and A. Heredia, (2006). Dietary fibre from vegetable products as a source of functional ingredients. Trends in Food Sciences and Technology, 3-15.

Publisher | Google Scholor - Figuerola, F., M.L. Hurtado, A.M. Estevez, I. Chifelle and F. Asenjo, (2005). Fibre concentrates from apple pomace and citrus peel as potential fibre sources for food enrichment. Food Chemistry, 91:395-401.

Publisher | Google Scholor - Lario, Y. E. Sendra, J. Garcia-Perez, C. Fuentes, E. Sayas-Barbera, et.al. (2004). Preparation of high dietary fiber powder from lemon juice by-products. Innovative Food Science & Emerging Technologies. 5:113-117.

Publisher | Google Scholor - Larrauri, J.A. (1999). New approaches in the preparation of high dietary fibre powders from fruit by products. Trends in Food Science and Technology, 3-8.

Publisher | Google Scholor - Jin, Z., F. Hsieh and H.E. Huff, (1995). Effects of soy fiber, salt, sugar and screw speed on physical properties and microstructure of corn meal extrudate. Journal of Cereal Science, 22:185-194.

Publisher | Google Scholor - Stojcesk, V., P. Ainsworth, A. Plunkett and S. Íbanoglu, (2008). The recycling of brewer’s processing by-product into ready-to-eat snacks using extrusion processing. Journal of Cereal Science, 47:469-479.

Publisher | Google Scholor - Imoisi, C., J.U. Iyasele, E.E. Imhontu, D.O. Ikpahwore and A.O. Okpebho, (2020). Pasting properties of composite of cassava and wheat flours. Journal Chemical Society of Nigeria, 45(6): 1157-1163.

Publisher | Google Scholor - Imoisi, C., J.U. Iyasele and S.E. Okhale, (2021). Proximate and acute toxicity profile of Vitex doniana (Black Plum) fruit. Journal Chemical Society of Nigeria, 46(2): 276-282.

Publisher | Google Scholor - Imoisi, C. and U.C. Michael, (2020). Comparative physicochemical and proximate analyses of different extracts of Persea americana. Journal Chemical Society of Nigeria. 45(6):1139-1146.

Publisher | Google Scholor - Ajenu, C.O., C. Imoisi, E.E. Imhontu, and U.R. Orji, (2021). Comparative evaluation of the proximate and micro-nutritional benefits of pawpaw, carrot, turmeric and coconut. Journal of Food Technology and Nutrition Science, 3(3):1-5.

Publisher | Google Scholor - Dhingra, D., (2012). Dietary fibre in foods: A review. Journal of Food Science Technology. 49: 255-266.

Publisher | Google Scholor - Martin, K. (1999). Replacing fat, retaining taste. Food Engineering International, 24:57-59.

Publisher | Google Scholor