Research Article

Studies on the Nutritional Anti-Oxidant and In-Vitro Anti-Diabetic Properties of Functional Cookies Produced from Millet Defatted Soya Beans and Cinnamon Flour Blends

- Ogunjemilusi M.A *

- Ajisefinni F.K

- Alaba J.O, Adeniji

Department of Surgery of the College of Medicine of the University of Lagos/Lagos University Teaching Hospital, Idi-Araba, Surulere, Lagos, Nigeria.

*Corresponding Author: Ogunjemilusi M.A, Department of Surgery of the College of Medicine of the University of Lagos/Lagos University Teaching Hospital, Idi-Araba, Surulere, Lagos, Nigeria.

Citation: Ogunjemilusi M.A, Ajisefinni F.K, Alaba J.O, Adeniji. (2022). “Studies on the Nutritional, Anti-oxidant and In- Vitro Anti-diabetic Properties of Functional Cookies Produced from Millet, Defatted Soya Beans and Cinnamon Flour Blends”, International Journal of Nutrition Research and Health, BRS Publishers. 1(1); DOI: 10.59657/2871-6021.brs.22.001

Copyright: © 2022 Ogunjemilusi M.A, this is an open-access article distributed under theterms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Received: October 15, 2022 | Accepted: October 24, 2022 | Published: November 01, 2022

Abstract

This study evaluated the nutritional, antioxidant and anti-diabetic properties and anti-diabetic potentials of blends Millet, Defatted Soya beans and Cinnamon flours for functional cookies using Date as a natural sweetner. The crude protein content of the experimental samples ranged between 10.27 % and 13.54 %. The crude fibre of the samples ranged from 2.54-4.0 %. The ash content for the experimental composite flour ranged from 2.10- 2.39 % while the ash content of millet, defatted soyabeans and cinnamon flours are 2.78 %, 3.86 % and 2.29 % respectively. The fat content ranged from 3.18 %- 6.10 %. However, the functional properties of the flour blends increased as the inclusion of soyabeans flour increased after evaluating the bulk density, swelling capacity, oil and water absorption capacity of the blends used for the functional cookies. There was also increase in the nutritional properties of the functional cookies as the inclusion of soyabeans flour increased. The protein content of the UMMF cookies samples ranged from 13.03-17.17 %. The fiber content of the UMMF cookies samples increased from 2.39-3.18 %. The fat content for UMMF cookies samples ranged between 8.33-12.55 %. The ash content ranged from 3.21 to 5.03 for UMMF cookies. The properties determined for antioxidant were DPPH, FRAP and metal chelation which ranged from 51.64% to 48.39%, 0.66-0.92% and 30.45-31.96% respectively. Enzyme inhibition for UMMF cookies samples increased with increase in supplementation with soyabeans flour and inclusion of cinnamon flour which is reported to have anti-diabetic properties. Addition of defatted soya beans flour and cinnamon to unmalted and malted millet flour produced a noticeable effect on color, taste, flavor, texture, crispiness and overall acceptability on the cookies produced.

Keywords: nutritional anti-oxidant; anti-diabetic; cookies; soya beans; cinnamon flour blends; bulk density; swelling capacity; oil; water

Introduction

Functional food goes by many closely related definitions around the world [7]. One point of view is that functional food has a significant physiological effect on human health as it can be a source of essential nutrients [14]. If a food has the claim of improving health and associated with therapies, it is known as functional.

A latest trend in food industry is the incorporation of other flours form other plant sources in producing a functional food and this is due to its high demand. Thereby increasing the use of these flours (legume and cereals) in production of functional cookies due to their health benefits and ability to reduce risk of several diseases (Ayo et al., 2018). There is therefore a need to utilize composite flour from cereal and legume sources for this research work.

Millet grains are gluten-free, non-acid-forming, easy to digest with low glycemic index foods which is known to be good for people with celiac and diabetes as consumption of the grain assist in the regulation of blood glucose level. The grains are substantially rich in dietary fibre, carbohydrates, iron and calcium. The grain is also rich in phytochemicals, including phytic acid, which is believed to lower cholesterol, associated with reduced cancer risk.

Cinnamon is a spice from bark of Cinnamomum. Though, it is a condiment but investigation into its health benefit and phytochemical presence. The research on functional ingredients in food is not only limited to phytochemicals, but also the revelation of new effects of traditional nutritional ingredients such as cinnamon flour is continuously carried out [16]. Hence, the need for the inclusion of cinnamon in this work. Cinnamon is known to have strong antioxidant activity which correlates well with the phenolic compounds in the bark essential oil. It has been reported to have anti-inflammatory, anti-microbial, antibacterial, antitumor, cardiovascular, cholesterol-lowering, immunomodulatory, larvicidal, and antioxidant properties [13]. Soybean is a valuable crop worldwide mainly because of soybean meal’s nutritional efficacy as a food and feed ingredient. It has high protein content, balanced essential amino acid profile, and the presence of other beneficial nutrients all contribute to its economic and nutritional value. The key advantages of soya are its high protein content, vitamins, minerals and insoluble fiber. Soybeans are helpful in preventing diarrhoea, constipation and diabetes in the health sector of the economy [15]. The general objective of the study is to obtain a low glycemic index flour blend from millet, soybeans and cinnamon and utilize it for the production of functional cookies with a view to make functional cookies readily available for diabetic patients, celiac patient and a view to reducing dependence on the wheat.

Materials & Methods

Materials

Materials to be used in the production of the functional cookies include, millet flour, defatted soya beans flour, cinnamon, date (natural sweetener) butter, milk powder, salt, water, butter essence, baking powder, calcium propionate.

Preparation of Materials

Preparation of Whole Millet Flour

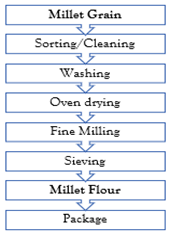

Whole millet flour was obtained by cleaning to remove dirt, stones and other extraneous materials. It was dry milled, sieved and packaged as shown in figure 1.

Preparation of Defatted Soya beans flour

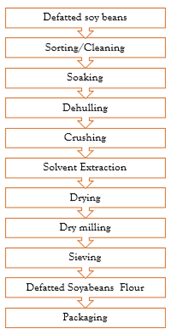

The soya beans will be cleaned from dirt by sorting out contaminants such as sands and any other evident impurities, crack, dehulled, milled and extracted with solvent through FDS (Flash Desolventising System) technology., then the cake is dry milled and sieved into fine flour, by passing them through a 2 mm mesh sieve as shown in Figure 2.

Preparation of Cinnamon powder

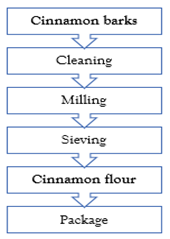

The Cinnamon barks will be cleaned from dirt by sorting out contaminants such as sands and any other evident impurities, then washed and oven dried. The barks will be dried and milled using attrition mill and sieved into fine flour, by passing them through a 0.35 mm mesh sieve as shown in fig 3.

Figure 1: Flow diagram for the production of Millet Flour

Figure 2: Flow diagram for the production of Soyabeans flour

Figure 3: Flow diagram for the production of Cinnamon flour

Table 1: The Formulation of Cookies Blends.

| Blend | Formulation |

| Blend 1 | 75% MF+20% DSF+5 Percent CF |

| Blend 2 | 65% MF+30% DSF+5 Percent CF |

| Blend 3 | 55% MF+40% DSF+5 Percent CF |

MF- Millet flour; DSF- Defatted Soybeans flour; CF- Cinnamon flour

Preparation of Functional cookies

A process of development of cookies was adopted as given by [32] with modifications.

Table 2: Formulation of Cookies using Millet, Defatted Soyabeans and Cinnamon Flour Blends. (Weight of ingredients shown as percentage of flour weight).

| Ingredient (g/100g flour) | Blend 1 | Blend 2 | Blend 3 |

| MF | 75 | 60 | 55 |

| CF | 5 | 5 | 5 |

| DSF | 20 | 30 | 40 |

| Corn starch | 20 | 20 | 20 |

| Milk | 13 | 13 | 13 |

| Date (Natural sweetner) | 27 | 27 | 27 |

| Whole egg | 10 | 10 | 10 |

| Butter | 7 | 7 | 7 |

| Water | 20 | 20 | 20 |

| Baking Powder | 3.0 | 3.0 | 3.0 |

MF- Millet flour; DSF- Defatted Soybeans flour; CF- Cinnamon flour

Functional Properties

(a). Water absorption capacity (WAC)

The WAC will be determined at room temperature following the [30] method.

(b). Oil absorption capacity (OAC)

The OAC will be determined at room temperature following the [30] method.

(c). Swelling capacity index

The method of [31] with slight modification was used to determine the swelling power of all samples

(d). Packed Bulk Density

The packed bulk density of the flour samples was determined according to the method of [4]

Proximate Analysis

The proximate composition of the cookies will be determined. Their moisture, crude protein (N × 6.25), fat, ash and fibre contents will be determined by standard procedures [8] and the total carbohydrate will be calculated by difference. All analyses will be carried out in triplicates.

Antioxidant Properties Determination

2, 2-diphenyl-2-picrylhydrazyl hydrate; ferric reducing antioxidant power and metal chelating assay were determined in sequence.

(a). 2,2- diphenyl-2-picrylhydrazyl hydrate (DPPH) assay

The radical scavenging ability of the samples was determined using the stable radical DPPH (2, 2-diphenyl-2-picrylhydrazyl hydrate) as described by [23].

(b). Determination of Ferric reducing antioxidant power (FRAP)

The principle of FRAP method will be based on the reduction of a colourless ferric tripyridyltriazine complex to its blue ferrous coloured form due to the donation of electron by antioxidant compounds. The ferric reducing antioxidant power (FRAP) assay was carried out according to the method of [27].

(c). Metal chelating ability assay

The metal-chelating assay of the samples will be carried out according to the method of [29].

Anti-diabetic properties

(i) Inhibition of α-glucosidase activity

This assay was carried out using the method described by [9] with slight modification.

(ii) Inhibition of α-amylase activity

The α-amylase inhibition assay was carried out according to the method of [33].

Result and Discussion

Proximate Composition of Millet, Defatted Soya and Cinnamon and their Blends

The proximate composition of millet, defatted soya beans and cinnamon flours are represented on Table 1. The value of the moisture content for the flours used for producing the composite flour for this study are reported as 8.45 % for unmalted millet flour8.27 % for soya flour and 6.15 % for cinnamon flour. The moisture content of combined mixture of unmalted millet, defatted soya and cinnamon flour is between the range of (8.83% – 9.11%) with the highest value in sample UMMF3 (9.11%) and the lowest value in sample UMMF1 (8.83%). Moisture contents obtained from this study is higher than range of moisture (3.34-4.06%) reported by [18] but lower than those obtained by [21] which ranged from 7.24 – 9.80% for wheat and full fat soybeans cookies. This observation implies that the spoilage period of the flour would be longer, since the moisture content of the flour samples was very low for the activity of microorganisms; and this finding agreed with other reports for flour samples [11][6]

The crude protein content of the flours that make up the composite flour are 9.69 % for millet flour, 9.13 % for defatted soya flour and 2.61 % for cinnamon flour. The crude protein content of the experimental samples ranged between 10.27 % and 13.54 % for samples having unmalted millet flour as its main flour (UMMF1-3). UMMF3 had the highest value of 13.54 %. This observation could be attributed to the inclusion of defatted soya flour, which is also high in protein [11]. It is evident that combination of two or more varieties cereals and legumes usually increased the protein quality of the overall products.

The crude fibre for the flours that make up the composite are 3.79 % for millet flour 6.57% for soya beans flour and 28.42 % for cinnamon flour. The crude fibre of the samples ranged from 2.54-4.0 % in UMMF samples. Nutritionally, consumption of these experimental dough meals from malted millet flour would be of benefits to the consumers, since, evidences have shown that dietary fibres promote good health by prevent degenerative diseases like diabetes and hypertension [22]. It is expected that the high content of crude fibre in cinnamon and soyabeans should have great influence on the experimental flour samples. However, the values obtained could be as a result of the 5% level of cinnamon flour added and varied quantities of the defatted soya beans flour.

Table 3: Proximate Composition of Millet, Defatted Soya beans, Cinnamon flours and their Blends

| Sample | Moisture | Fibre | Ash | Protein | Fat | Carbohydrate |

| MF | 8.45±0.32d | 3.79±0.06d | 2.78±0.13b | 9.69±0.06e | 1.38±0.04e | 73.91a |

| DSF | 8.27±0.04d | 6.57±0.06b | 3.86±0.03a | 9.13±0.07a | 2.20±1.39d | 69.97c |

| CIN | 6.15±0.07e | 23.42±0.11a | 2.29±0.04c | 2.61±0.02f | 3.70±0.20c | 61.83e |

| UMMF1 | 8.83±0.08bc | 2.54±0.03e | 2.10±0.04d | 10.27±0.03d | 3.18±0.06c | 73.08a |

| UMMF2 | 8.95±0.04a | 2.88±0.04d | 2.28±0.04c | 11.07±0.02c | 4.67±0.03b | 70.15b |

| UMMF3 | 9.11±0.03ab | 4.0±0.03c | 2.39±0.03c | 13.54±0.05b | 6.10±0.03a | 64.86d |

MF- Millet flour; DSF- Defatted Soybeans flour; CF- Cinnamon flour, UMMF1: 75% UMMF+20%DSF+5 Percent CF; UMMF2: 65% UMMF+30%DSF+5 Percent CF; UMMF3: 55% UMMF+40%DSF+5 percent CF

Functional Properties of Millet, Defatted Soyabeans and Cinnamon flour Blends

The results of the functional properties of millet, defatted soya-cinnamon composite blends are presented in Table 2. The defatted soyabeans flour had its bulk density as 0.66 g/ml and millet flour as 0.59 g/ml. The bulk density (BD) improved significantly for the composite flour with increasing the level of soybean and cinnamon flour. The results indicated that supplementation of millet with soybean and cinnamon flour improved significantly (P ≤ 0.05) the bulk density of millet. The bulk density for UMMF samples ranged from 0.59-0.70 g/ml. The values obtained could be slightly compared to the value of bulk density for plantain-soyabeans-cinnamon flour (0.52 to 0.68 g/ml) by [2]. However, values obtained from this study were comparable with the values reported by [26] for cowpea (0.60 g/ml) and also for pearl millet as reported by [29]. The differences in the values of bulk density between this study and previous ones are likely due to be product and varietal differences [12].

The water absorption capacity (WAC) of UMMF samples ranged from 165- 174 %. An increase trend was observed for the oil absorption capacity. With increase in the formulation there happens a more starch damage than 100% millet flour by blending process. With high proportion of starch damage, water absorption rises, and it realizes high starch gelatinization and finally the crumb becomes softer. The WAC and OAC values of the MMF samples increased as the inclusion of CIN and DSF increased which is in agreement with the findings of [2,3].

The oil absorption capacity (OAC) of UMMF samples ranged from 147- 117 %. The OAC values of the MMF samples increased as the inclusion of CIN and DSF increased. Though, the oil-absorption capacity of all flour blends suggests that it is not useful for baking alone but would also be useful in formulation of foods where oil absorption property is an important consideration. [10] reported OAC ranging from 1.75 to 2.21 g/g for rice, cassava and kersting’s groundnut composite flour. Variation in oil absorption capacity might be due to the different proportion of the protein molecules present in each of the samples.

The swelling capacity of flours depends on size of particles, types of variety and types of processing methods or unit operations. The temperatures for determining the swelling capacity of experimental flour samples varied as three temperatures were used. The temperatures used were 70, 80, 90 oC. The values of swelling capacity obtained in this study ranged from 198.67 to 226.33 % for UMMF samples at 70 °C, 229-239 % for UMMF samples at 80 °C and 237 – 334.7 % for UMMF samples at 90 °C. The swelling capacity of defatted soya flour also ranged from 233-286 % as temperature increased. It was also noted that as temperature increased, the swelling capacity of the flour increased. The result obtained might be due to the different proportion of the protein molecules present in each of the samples [11].

Table 4: Functional Properties of Millet, Soya Beans Cinnamon and Composite Flours

| Sample | B.D (g/ml) | WAC (%) | OAC (%) | S.C 70 (%) | S.C 80 (%) | S.C 90 (%) |

| UMMF | 0.59±0.01d | 184±1.00bc | 189.7±1.53cd | 206.3±1.53d | 236±0.26g | 253.7±1.53de |

| DSF | 0.66±0.06cd | 195±2.08a | 122.3±1.73a | 233.3±2.31b | 275±0.06g | 286±2.00de |

| UMMF1 | 0.59±0.02d | 165±2.52e | 147.3±1.15b | 198.7±1.53d | 229±1.15h | 237±1.00f |

| UMMF2 | 0.67±0.02cde | 174±3.56d | 120.7±1.53de | 222±2.00d | 232±2.00h | 311±1.15cd |

| UMMF3 | 0.70±0.02bc | 186.7±3.21c | 117±4.35e | 226±2.89c | 239±2.08f | 334.7±2.08bc |

MF- Millet flour; DSF- Defatted Soybeans flour; CF- Cinnamon flour, UMMF1: 75% UMMF+20%DSF+5 percent CF; UMMF2: 65% UMMF+30%DSF+5 percent CF; UMMF3: 55% UMMF+40%DSF+5 percent CF

Proximate Composition of Functional Cookies produced from Millet, Defatted Soyabeans and Cinnamon Flour Blends

The study was carried out to understand the influence of blend ratio (millet: defatted soya: cinnamon flour), upon the nutritional and Overall acceptability of cookies. The prime objective of defatted soy flour and cinnamon flour incorporation in preparation of composite flour for the functional cookies was to enhance its nutritional value, its anti-diabetic properties, antioxidant properties. Hence, during present investigation, cookies prepared with different concentration of defatted soy flour and cinnamon at 5 % for all samples were analyzed for its proximate composition and the obtained results are given in Table 3. It could be seen from the Table 3 that increase in concentration of DSF in cookies has significant effect on its proximate composition.

The moisture content of cookies decreased linearly with increase in concentration of DSF, this may be attributed to high water binding capacity of DSF which is retaining higher moisture content in ultimate product. There was no significant difference (p less than ) in the moisture content of the samples. The moisture content for the MF cookies samples decreased from 5.43-5.08%. Low moisture content is important in cookies production as it limits the water available for microbial activity and thereby resulting into a stable product with longer shelf life. The values obtained are close to those obtained by [20] for sorghum-soybean-finger millet biscuits who observed there was decrease from 3.78% to 3.27% while substitution of soybean flour from 10% to 50%.

The protein content of the cookies increased with increasing in the percentage substitution of soybean flour in the cookies dough blends. The increase in the protein content of the cookies could be due to the significant quantity of protein in soybean seeds. Soybeans have been reported to be a good source of cheap protein. The protein content of the UMMF cookies samples ranged from 13.03-17.17 %. These values are higher than the protein content (7.06% to 11.84%) of sorghum-wheat composite flour biscuits reported by Adebowale et al., (2012).

Table 5: Proximate Composition of Cookies from Millet, Defatted soya and Cinnamon flour blends

| Sample (cookies) | Moisture (%) | Fibre (%) | Ash (%) | Protein (%) | Fat (%) | Carbohydrate (%) |

| UMMF1 | 5.43±0.25b | 2.39±0.00c | 3.21±0.68a | 13.03±0.29a | 8.53±0.24c | 70.04±0.48d |

| UMMF2 | 5.38±0.88ab | 2.58±0.00b | 3.83±0.71b | 13.47±0.58c | 10.43±0.10b | 73.75±0.35bc |

| UMMF3 | 5.08±0.35ab | 3.18±0.00a | 5.03±0.05c | 17.17±0.57a | 12.53±0.01a | 73.08±0.61c |

UMMF1: 75% UMMF+20%DSF+5 Percent CF; UMMF2: 65% UMMF+30%DSF+5 percent CF; UMMF3: 55% UMMF+40%DSF+5 percent CF

The fiber content of the UMMF cookies samples increased from 2.39-3.18 % as the defatted soyabeans inclusion increased from 20% to 40%. Nutritionally, consumption of these experimental dough meals from malted millet flour would be of benefits to the consumers, since, evidences have shown that dietary fibres promote good health by prevent degenerative diseases like diabetes and hypertension [22]. Cinnamon has high fibre content. Therefore, the inclusion of cinnamon in composite flour for cookies enhanced its nutritional constituents and hold the potential to deliver safe foods for obese, hypertensive, diabetic patients, and patients with colon disease.

The fat content values increased with increase in quantities of soyabeans flour incorporated. The fat content for UMMF cookies samples ranged between 8.33-12.55 %. Though a defatted soya beans flour was used in the study but it still contains essential fattyl acid. Legumes are said to contain oil. The other ingredients used for the production of cookies such as margarine could contribute to the fat content. The values obtained in this study for fat are lower than the values (17.61-20.54 %) reported by [2, 3] for the production of cookies from plantain, groundnut and cinnamon blends.

The ash content ranged from 3.21 to 5.03 for UMMF cookies. Ash is indicative of the amount of minerals contained in any food sample. Hence, UMMF cookies sample may have high mineral contents when analysed for it. Carbohydrate contents are generally high. This will have good energy effects.

Antioxidant Properties of the Cookies

The results of antioxidants activities of the cookies are presented in Table 4. The cookies were evaluated for DPPH, metal chelating ability and ferric reducing antioxidant power (FRAP). The free radical scavenging activities of the cookie’s extracts were concentration dependent for the antioxidant properties evaluated.

DPPH• scavenging activity as shown in Table 4 ranged from 51.64% to 48.39% for UMMF cookies samples. UMMF1 (51.64%) and UMMF2 (48.86%) also exhibited significantly high radical scavenging activities. The formulated cookies (were observed to scavenge the DPPH• better. The results obtained in the present study are higher than those reported by [1] for wheat–bambara cookies.

Unmalted cookies sample showed progressive increase in FRAP as the soyabeans and cinnamon flour inclusion increased. This shows the potency of the cereal not malted to have antioxidant ability. The ability to reduce Fe3+ to Fe2+ by the cookies increased with increase in supplementation with soyabeans and cinnamon flour which may be attributed to the ability of incorporated cinnamon and soyabeans flour to form reductants that could react with the free radicals thereby stabilizing and terminating the radical chain [24].

Table 6: Antioxidant Properties of Cookies Produced from Millet, Defatted Soya Beans and Cinnamon Flour

| Sample | Frap (%) | Dpph (%) | Metal chelation (%) |

| UMMF1 | 0.66±0.01c | 51.64±0.31a | 31.96±0.13a |

| UMMF2 | 0.86±0.05b | 48.66±0.11b | 30.87±0.09b |

| UMMF3 | 0.92±0.02a | 48.39±0.74b | 30.45±0.27b |

UMMF1: 75% UMMF+20%DSF+5 Percent CF; UMMF2: 65% UMMF+30%DSF+5 Percent CF; UMMF3: 55% UMMF+40%DSF+5 Percent CF

Inhibition of α-amylase and α-glucosidase activities

a. α-amylase inhibition

The percentage α-amylase inhibition of millet-soyabeans-cinnamon is presented in Table 5 and Figure 1. The result depicts that percentage inhibition was concentration dependent. It was observed the UMMF had higher values indicating the cereal (millet) also has high potency to inhibit amylase with UMMF1 showing inhibitory activity of 44.09 % at 0.1 concentration and 68.86 at 0.2 concentration. This discovery in this study agrees with previous reports which ascertained that plant phytochemicals and underutilized legumes inhibited salivary and pancreatic α-amylase activities [5][25]. The results obtained for alpha amylase inhibition in this study is similar to those obtained (23.59 -54.22%) by Olagunju et al., 2018 from the development of value-added nutritious crackers with high antidiabetic properties from blends of Acha (Digitaria exilis) and blanched Pigeon pea (Cajanus cajan)

The percentage α-glucosidase inhibition of millet-soyabeans-cinnamon cookies is presented in Table 5. The results depict that percentage inhibition was concentration dependent as activities increased with increase in concentration of cookies extract, and higher concentration (10 mg/ml) was required to achieve significant inhibitory activity. Enzyme inhibition for UMMF cookies samples increased witAh increase in supplementation with soyabeans flour.

Table 7: In-vitro Anti-diabetic Properties of functional cookies from Millet, Defatted Soyabeans and Cinnamon Flour Blends

| α -amylase | α-glucosidase | |||

| Sample | Conc0.1mg/ml | Conc. 0.2 mg/ml | Conc. 0.1mg/ml | Conc. 0.2 mg/ml |

| A | 43.45±0.15a | 65.32±0.19a | 44.09±0.14b | 68.86±0.19a |

| B | 40.93±0.07b | 61.66±0.01c | 43.57±0.06c | 66.86±0.19c |

| C | 38.88±0.59c | 60.39±0.19d | 38.36±0.11d | 66.47±0.19d |

| Acabose | 73.31 | 73.31 | 73.31 | 73.31 |

UMMF1: 75% UMMF+20%DSF+5 percent CF; UMMF2: 65% UMMF+30%DSF+5

References

- Adefegha S A, Oboh G. (2013). Sensory qualities, antioxidative activities and in vitro inhibition of enzymes relevant to Type-2 diabetes by biscuits produced from 5 wheat-bambara groundnut flour blends. International Journal of Food Engineering, 9(1): 17- 28.

Publisher | Google Scholor - Adegunwa M O, Bamidele B O, Alamu E O, Adebanjo L A. (2019). Production and Quality Evaluation of Cookies from Composite Flour of Unripe Plantain (Musa paradisiaca), Groundnut (Arachis hypogaea L.) and Cinnamon (Cinnamomum venum), Journal of Culinary Science & Technology, 1542-8044

Publisher | Google Scholor - Adegunwa M O, Bamidele B O, Alamu E O, Adebanjo L A. (2019). Production and Quality Evaluation of Cookies from Composite Flour of Unripe Plantain (Musa paradisiaca), Groundnut (Arachis hypogaea L.) and Cinnamon (Cinnamomum venum), Journal of Culinary Science & Technology, 1542-8044

Publisher | Google Scholor - Adeleke R O, Odedeji J O. (2010). Functional properties of wheat and sweet potato flour blends. Pakistan J Nutr, 9(6): 535–538.

Publisher | Google Scholor - Ademiluyi A O, Oboh G. (2012). Phenolic-rich extracts from selected tropical underutilized legumes inhibit α-amylase, α-glucosidase and angiotensin I converting enzyme in vitro. Journal of Basic and Clinical Physiology and Pharmacology, 23(1):17-25.

Publisher | Google Scholor - Akinjayeju O, Fagbemi T N, Ijarotimi O S. (2019). Optimization and evaluation of some physico-chemical and nutritional properties of cereal-based soya-fortified flours for functional dough meal. Journal of Advances in Food Science and Technology, 6: 40-59.

Publisher | Google Scholor - Alongi M, Anese M. (2021). ‘Re-thinking functional food development through a holistic approach’. Journal of Functional Foods, 81: 104466.

Publisher | Google Scholor - AOAC (2005). Official methods of analysis, 18th ed. Washington, D.C. Association of Analytical chemists.

Publisher | Google Scholor - Apostolidis E, Lee CM. (2010). In vitro potential of ascophyllum nodosum phenolic antioxidant-mediated-glucosidase and-amylase inhibition. Journal of Food Science, 75:97-102

Publisher | Google Scholor - Awolu O O, Oluwaferanmi P M, Fafowora O I, Oseyemi G F. (2015). Optimization of the extrusion process for the production of ready-toeat snack from rice, cassava and kersting’s groundnut composite flours.LWT Food Science and Technology, 64(1): 18-24.

Publisher | Google Scholor - Awolu O O, Omoba O S, Olawoye O. (2017). Optimization of production and quality evaluation of maize-based snack supplemented with soybean and tiger-nut (Cyperus esculenta) flour. Food Science and Nutrition, 5:3-13.

Publisher | Google Scholor - Bryant L A, Montecalvo J, Morey J R, Loy K S. (1988) “Processing, Functional and Nutritional Properties of Okra Seed Products,” Journal of Food Science, 55(3):810-816.

Publisher | Google Scholor - Charles D J. (2012). Cinnamon. In: Antioxidant Properties of Spices, Herbs and Other Sources. Springer, New York, NY.

Publisher | Google Scholor - Chen G. et al. (2021). ‘Functional foods and intestinal homeostasis: The perspective of in vivo evidence’. Trends in Food Science and Technology, 475–482

Publisher | Google Scholor - Cristina M S, Raquel M S. (2011). Soybean, Friend or Foe, pp 327 Chapter 17 Soybean and Nutrition. Edited by Hany A. El-Shemy.

Publisher | Google Scholor - Dong Linna, Shu Lianting, Wang Yuling. (2019). Correlation between Vitamin C and Vitamin E levels and preeclampsia [J]. Chinese General Practice, 8:1353-1355.

Publisher | Google Scholor - Gul S, S afdar M. (2009). Proximate composition and mineral analysis of Cinnamon. Pakistan Journal of Nutrition, 8(9):1456-1460.

Publisher | Google Scholor - Ikuomola D S, Otutu O L, Oluniran D D. (2017). Quality assessment of cookies produced from wheat flour and malted barley (Hordeum vulgare) bran blends, Cogent Food and Agriculture,3: 1293471.

Publisher | Google Scholor - Jakhetia V, Patel R, Khatri P, Pahuja N, Garg S. (2010). Cinnamon: A pharmacological review. Journal of Advanced Science Research, 1(2): 19-23.

Publisher | Google Scholor - Jayaweera A M U T, Premakumar K, Kumarasiri U W L M. (2018). Quality Evaluation of Freshly Prepared Biscuits from Composite Flour of Sprouted Sorghum, Soybean and Finger Millet. International Journal of Research Publications, 6(1).

Publisher | Google Scholor - Joel N, Fatima K, Stephen F. (2014). Production and quality assessment of enriched cookies from whol wheat and full fat soya. European Journal of Food Science and Technology, 2(2):19-29.

Publisher | Google Scholor - Lairon D, Arnault N, Bertrais S. (2005) et al. Dietary fibre intake and risk factors for cardiovascular disease in French adults. American Journal of Clinical Nutrition, 82 :1185-1194.

Publisher | Google Scholor - Li W, Pickard M D, Beta T. (2007). Effect of thermal processing on antioxidant properties of purple wheat bran. Food Chem. 104: 1080–1086.

Publisher | Google Scholor - Moktan B, Roy A, Sarkar P K. (2011). Antioxidant activities of cereal-legume mixed batters as influenced by process parameters during preparation of dhokla and idli, traditional steamed pancakes. International Journal of Food Science and Nutrition, 62(4): 360–369.

Publisher | Google Scholor - Nickavar B, Yousefian N. (2009). Inhibitory effects of six Allium species on α-amylase enzyme activity. Iranian Journal of Pharmaceutical Research, 8: 53–57.

Publisher | Google Scholor - Okaka N C, Potter N. (1979). Physico-chemical and Functional Properties of cowpea powder processed to reduce beany flavour. Journal of Food Science, 44(4): 1235-1240.

Publisher | Google Scholor - Oyaizu M. (1986). Studies on products of browning reaction-antioxidative activities of products of browning reaction prepared from glucosamine. Japanese Journal of Nutrition, 44(6): 307-315.

Publisher | Google Scholor - Rahimi-Madiseh M, Malekpour-Tehrani A, Bahmani M, Rafieian-Kopaei M. (2016). The research and development on the antioxidants in prevention of diabetic complications. Asian Pacific Journal of Tropical Medicine 9:825-831

Publisher | Google Scholor - Singh A, Yadav N, Sharma S (2012) Effect of fermentation on physicochemical properties and in vitro starch and protein digestibility of selected cereals. International Journal of Agriculture and Food Science, 2(3): 66-70.

Publisher | Google Scholor - Sosulski F, Garatt M and Slinkard A (1976) Functional properties of ten legume flours. Int J Food Sci Technol. 9: 66-69.

Publisher | Google Scholor - Takashi S, Seib PA (1988) Paste and gel properties of prime corn and wheat starches with and without native lipids. Cereal Chem 65(6): 474-483.

Publisher | Google Scholor - Aleem Zaker MD, Genitha TR, Hashmi SI (2012) Effects of Defatted Soy Flour Incorporation on Physical, Sensorial and Nutritional Properties of Biscuits. J Food Process Technol 3:149.

Publisher | Google Scholor - Bernfeld, P., 1955. Amylases, alpha and beta. In: Colowick, S.P., Kaplan, N.O. (Eds.), Methods in Enzymology. Academic Press, New York, pp. 149-158.

Publisher | Google Scholor